Mass Timber: Driving Sustainable Construction and Innovative Projects in B.C.

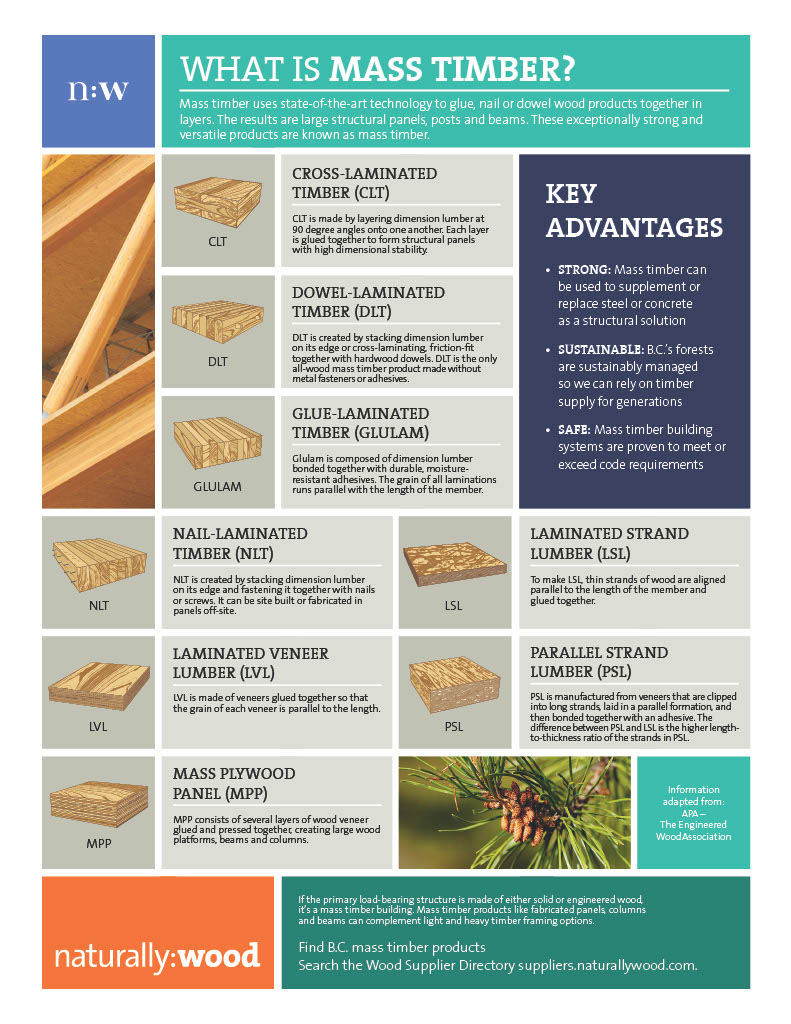

What is Mass Timber – The Basics

Source: Naturally Wood

Mass timber construction offers a wide range of benefits. When used properly, it is a sustainable material sourced from responsibly managed forests, with lower energy consumption and greenhouse gas (GHG) emissions compared to traditional building materials such as concrete and steel. Buildings account for 29% of energy used in BC and about 12% of provincial GHG emissions[1]. Mass timber sequesters carbon dioxide, reducing the overall carbon footprint of buildings. The use of prefabricated components ensures construction efficiency, with faster timelines and cost savings. It provides excellent structural performance, combining strength and lightweight properties, as well as inherent fire resistance and seismic resilience. Additionally, mass timber’s warm and natural aesthetics enhance indoor environments, promoting well-being and a connection to nature.

The B.C. Mass Timber Action Plan

Introduced by the government of B.C., the Mass Timber Action Plan outlines a strategic approach to promote and support the use of mass timber in construction. The plan aims to leverage the environmental, economic, and social benefits of mass timber, positioning B.C. as a global leader in the mass timber industry. It focuses on key areas such as market development, innovation and research, education and training, regulatory enhancements, and showcasing projects. The plan seeks to foster sustainable construction practices, stimulate economic growth, create job opportunities, and contribute to the reduction of carbon emissions by encouraging the use of mass timber as a viable and environmentally friendly building material.

Stable, predictable access to fibre is crucial for the growth of the mass timber sector in B.C. for several reasons: supply chain reliability, investment and planning, industry growth and job creation, and sustainability and environmental considerations.

Learn more: https://www2.gov.bc.ca/assets/gov/business/construction-industry/bc_masstimber_action_plan_2022.pdf

What about other prefabrication?

Prefabrication is a construction method that involves manufacturing building components or modules in a controlled factory environment before assembling them on-site, like Lego blocks. Mass timber is only one example of a prefabrication building system. Other types of prefabrication can include light-frame wood construction (panels) and modular construction.

Learn more: https://www.naturallywood.com/topics/prefabrication/

Mass timber projects shaping the future of B.C.’s landscape

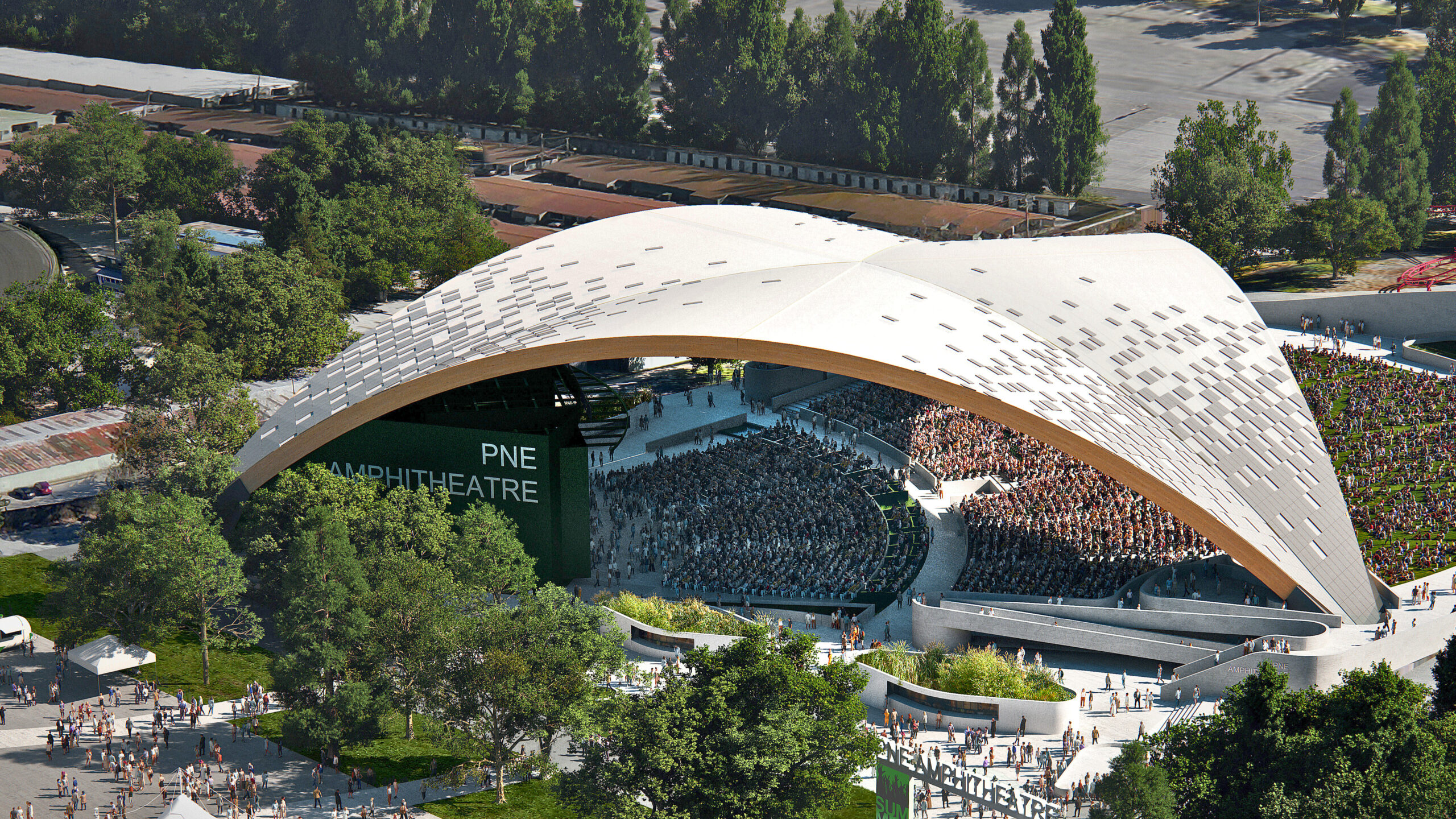

PNE Ampitheatre – Vancouver

- The PNE is building a brand new, state-of-the-art outdoor Amphitheatre with a capacity of approximately 10,000 and will provide much needed mixed-use venue space for top-tier concerts, arts and culture programming, community events, esports events, and more.

- Spectacular venue design incorporates daylighted stream, native greenery, and stunning natural vistas.

- Sustainable products and design; built using Passive House principles, LEED, and Salmon-Safe certification standards.

- One of the largest free-span timber roof structure in the world.

- Completion in 2026.

The Confluence Building – Castlegar

- The Confluence Building serves as an educational and exhibition space, highlighting the importance of sustainable construction practices and the versatility of wood in modern architecture.

- The project showcases recent mass timber technology with prefabricated cross-laminated timber (CLT) panels manufactured within 17 kilometres of the building site.

- The use of mass timber reduces labour costs and construction time and helps achieve Passive House certification, a key project feature.

- Precision-made prefabricated wood panels using computerized numerical control (CNC) achieve complex geometry while being cost-effective.

- Completion in 2023.

Burrard Exchange – Vancouver

- Burrard Exchange will be one of the tallest exposed mass timber office buildings in North America.

- The building will offer premium AAA-calibre office space, with large floor plates reaching up to 30,000 sq ft.

- A mix of indoor and outdoor retail, including restaurants, will pull people into the building and the core of the Bentall Centre site in downtown Vancouver.

- Completion date unknown.

District of Saanich Fire Station #2 Redevelopment – Saanich

- This fire station for the District of Saanich is one of the first mass timber buildings in Canada to target a zero-carbon building standard while being fully equipped for post-disaster response.

- Uses a steel and timber post and beam system supporting cross-laminated timber (CLT) floors, a CLT roof suspended from glue-laminated timber (glulam) beams, and a mass timber shear wall.

- Demonstrates how mass timber construction is well-suited for post-disaster and emergency facilities.

- Completion in 2025.

Kelowna International Airport Expansion – Phase I – Kelowna

- Expansion includes a two-storey mass timber and steel hybrid structure over a below-grade concrete basement and crawl space.

- The mass timber roof will be built from prefabricated panels to reduce on-site construction time and keep the airport facility fully operational throughout the renovation.

- Primary steel columns and glue-laminated timber (glulam) girders will be erected, followed by prefabricated cross-laminated timber (CLT) slabs.

- Completion in 2025.

[1] https://pics.uvic.ca/media-release/how-accelerate-energy-efficiency-bcs-buildings